Glass Industry

Glass Industry Machines

From cullet management to cold ends, SINEX is involved in every stage of glass product manufacturing. Our equipment is designed to ensure exceptional dosing reliability and durability in compositions.

Our underwater conveyors in cellars allow you to handle your waste effortlessly, ensuring years of continuous service.

With our unique expertise in cold end transfer, featuring several patented functions, SINEX is an essential partner for safely transporting these materials to the scale conveyor.

Our teams are here to provide you with the best of our experience.

Examples of processed products: cullet, groisil, soda ash, limestone, sand, additives, bottles, flasks, jars, etc.

Search by Functions

You can refine your product search by selecting multiple functions to find the machine that best suits your needs.

Electromechanical Rectangular Vibrating Conveyor

Vibration transport limits abrasion, prevents the creation of fines (no mechanical constraints on the product), and ensures a constant and controlled volumetric flow.

Suitable for extraction under silos, dosing, or transfer up to 10 meters, the electromechanical vibrating conveyor is the most versatile solution for all bulk industries.

Maintenance is facilitated by the absence of moving parts in contact with the product and the use of reliable vibrating motors, ensuring maximum availability.

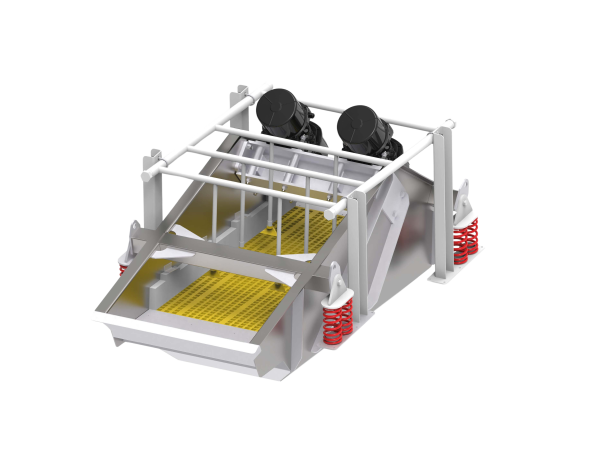

Electromechanical Vibrating Sieve

The electromechanical vibrating sieve is ideal for classification, safety screening, and dust removal of your bulk and powdery products. Available in open or sealed designs and in six sizes (from 0.65 to 6.9 m²), this range of inclined sieves offers an elliptical vibratory motion, ensuring high screening efficiency at an optimized cost due to its compact design. The quick change of screens (1 to 3 decks possible) and easy motor maintenance make it a reliable and ergonomic solution for your screening and sieving needs.

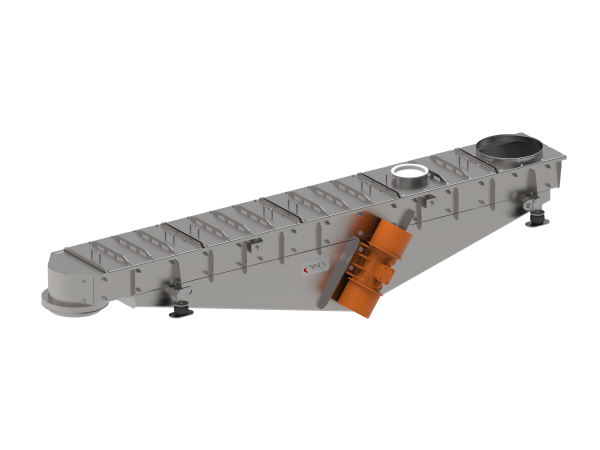

Extractor / Conveyor EME

Vibration transport limits abrasion, prevents the creation of fines (no mechanical constraints on the product), and ensures a constant and controlled volumetric flow. Suitable for extraction under silos, dosing, or transfer up to 10 meters, the electromechanical vibrating conveyor is the most versatile solution for all bulk industries. Maintenance is facilitated by the absence of moving parts in contact with the product and the use of vibrating motors, ensuring maximum availability.

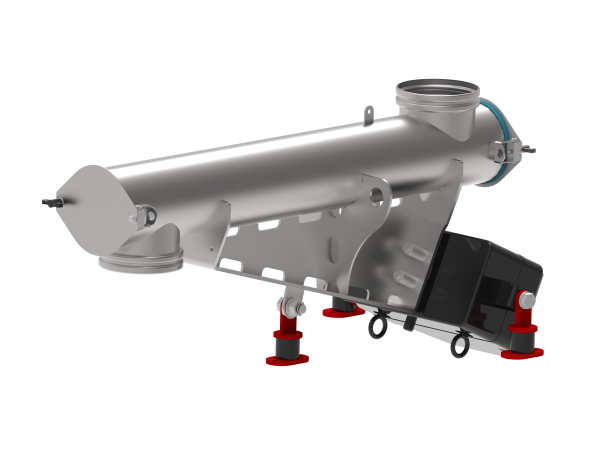

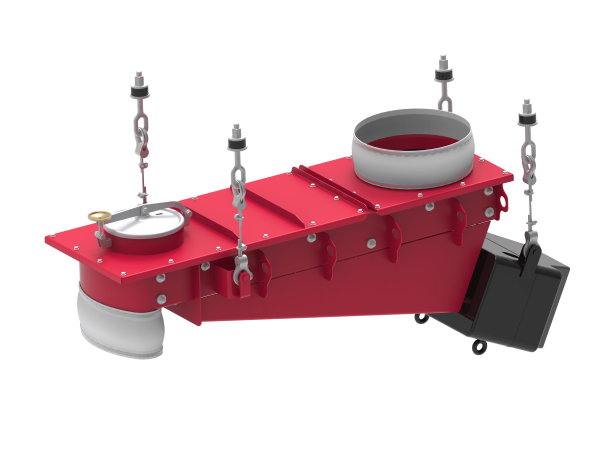

Electromagnetic Tubular Feeder

A sealed transfer solution, the tubular vibrating feeder is suitable for the extraction, dosing, and transport of your bulk and powdery products. The use of electromagnetic motors allows for a continuous and instantaneous flow variation from 0 to 100%, ensuring precise dosing for a controlled and repeatable recipe.

Electromechanical Vibrating Tubular Conveyor

Vibration transport limits abrasion, prevents the creation of fines (no mechanical constraints on the product), and ensures a constant and controlled volumetric flow. Suitable for extraction under silos, dosing, or transfer up to 8 meters, the vibrating tubular conveyor is the sealed solution ideal for all bulk industries.

Maintenance is facilitated by the absence of moving parts in contact with the product, as well as the use of reliable motorization (vibrating motors or magnetic bases) ensuring maximum availability.

Electromechanical Vibrating Screen

The electromechanical vibrating screen is ideal for the classification, safety screening, and dedusting of your bulk and powdery products.

Since screening is a crucial step in your process, our devices are custom-designed to perfectly meet your needs.

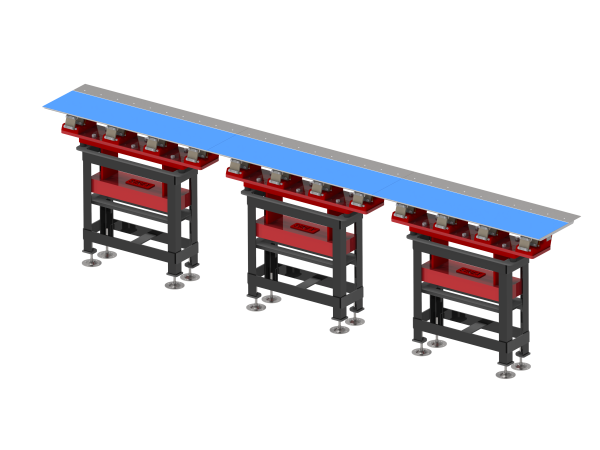

Vibrating Plates

The transfer of cold ends from the annealing lehr belt to the scalloped belt or accumulation belt is a critical moment. To address the challenges faced by glassmakers, SINEX has developed a patented technology that offers significant productivity gains. SINEX equipment delivers proven results in glassworks worldwide and easily integrates into your line between the cooling lehr, the scalloped belt, or the accumulation belt (less than 400 mm). They adapt to all line widths thanks to our modular design.

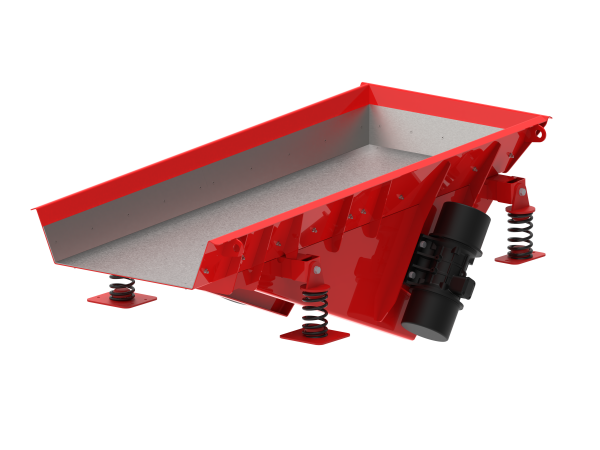

Electromagnetic Rectangular Feeder

An open or sealed transfer solution, the vibrating electromagnetic feeder is ideal for the extraction, dosing, and transport of your bulk and powdery products up to 4.5 meters. Thanks to the use of electromagnetic motors, the flow rate can vary from 0 to 100% continuously and instantly, allowing precise dosing to ensure a controlled and repeatable recipe. Moreover, vibration transport limits abrasion and prevents the creation of fines, as there is no mechanical constraint on the product.

Drainer

The drainer allows for liquid/solid separation of sludge or a product stream following a washing phase (water, acids, etc.). Installed on an upward slope and equipped with polyurethane or metal screens (up to 400 microns), this equipment reduces the liquid content in the outgoing solid phase to just a few percent. Equipped with spray bars, it combines the washing and draining phases by collecting the loaded water through overflow into a static tank.

Vibrating Bin activator

Installed under a silo, the SINEX bin activator is a simple and reliable solution to facilitate the flow and extraction of products prone to arching. The anti-load cone transmits vibration to the product in contact, breaking the arching effect.

The product flow, passing through an annular section, is freed from static load, thus preventing clogging in the product outlet cone.